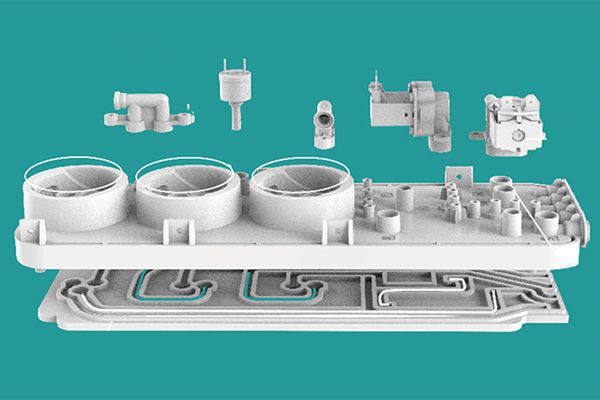

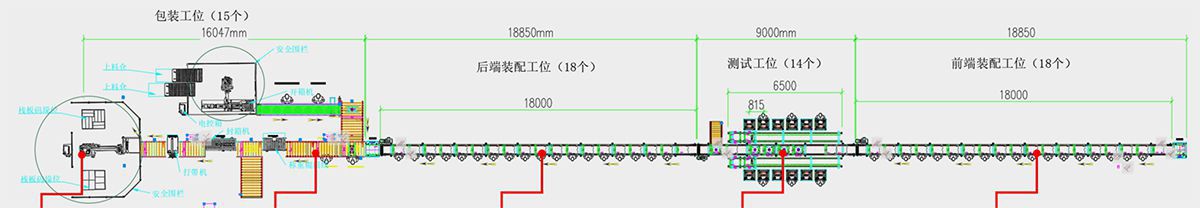

Aibote possesses a 65,000m2 smart factory, and a 4000m2 building for R&D, and testing. Our factory is equipped with 6 automatic production lines for injection molded parts, 100 digital injection molding machines, 9 RO membrane production lines, and automatic production and testing equipment for filter cartridges, electronic components, waterway boards, etc. In addition, we are equipped with 1 automatic production line for water purifier parts, and 4 assembly lines, enabling us to supply around 10,000 units per day. So far, more than 60% of parts are manufactured by Aibote, and the automation level during assembly exceeds 34%. Due to the well-equipped factory, the annual capacity of water purifier reaches 3 million units.

Our manufacturing plant comes equipped with 56 injection molding machines, 10 rotary melting furnaces, 5 filling machines, 8 welding machines, 4 sintering machines, 5 PP meltblown fabric machine, allowing us to perform processes of mold making, injection molding, rotary melting, sintering and welding to independently produce filter elements.

Smart injection molding line

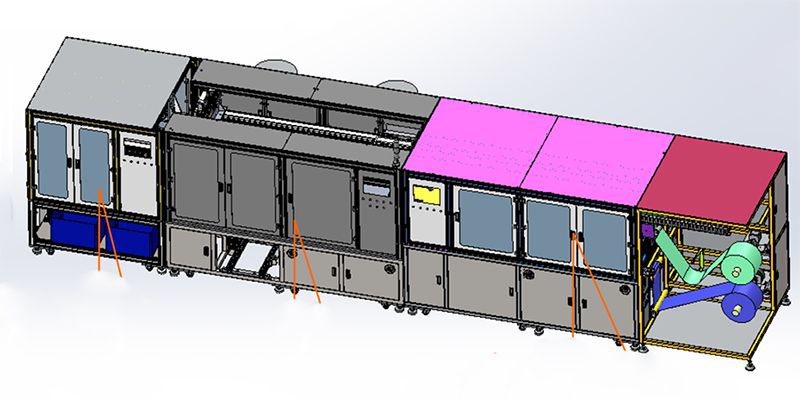

Automatic water filter system line

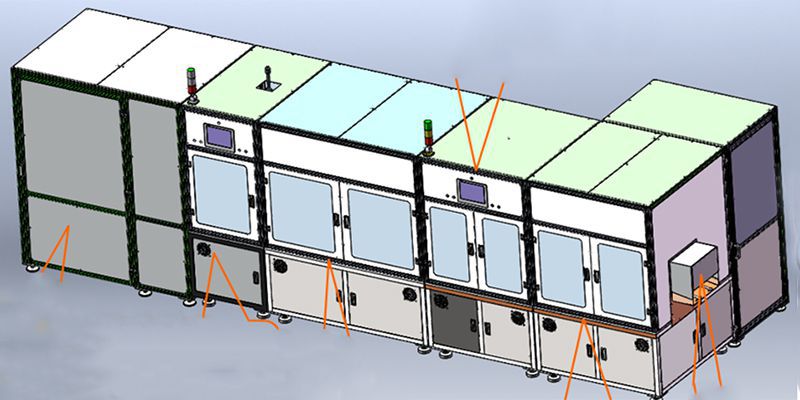

Automatic ultrasonic welding line

The ultrasonic welding line is equipped with automated units imported from world's reliable supplier to provide high welding quality while increasing working efficiency.

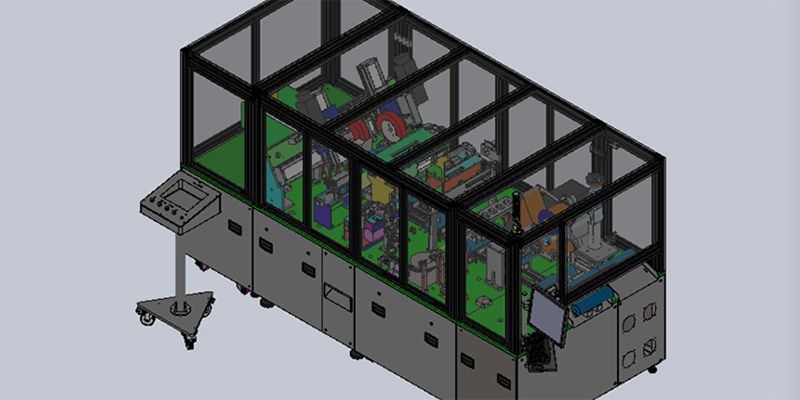

Automatic filter cartridge assembly line

The filter cartridge assembling line is equipped with automated units imported from world's reliable supplier to provide high product quality while increasing working efficiency.

Automatic RO membrane roll production line

At our RO membrane roll workshop, we set up a cleanroom system to make the workshop comply with the requirement to be a clean room.

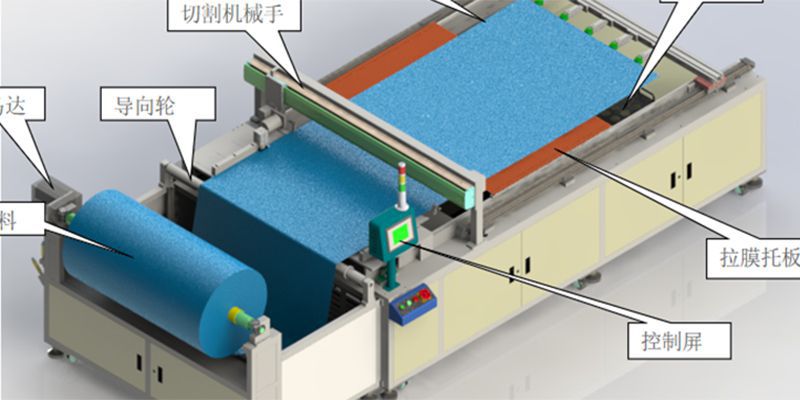

Automatic cross-cutting machine

Automatic cross-cutting machine Automatic membrane cutting, labeling and coding machine

Automatic membrane cutting, labeling and coding machine Automatic RO membrane rolling machine

Automatic RO membrane rolling machine