-

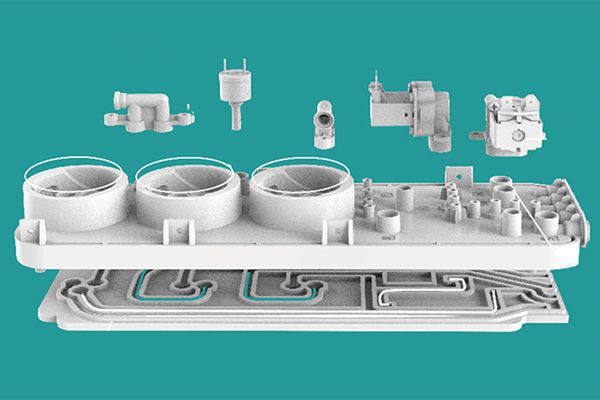

- Patented Technology6S compact waterway board features an ultra-simple design that enables the traditional water filter system with more than 80 components and more than 40 connection ports to be significantly simplified to approximately 20 components and 13 quick connection ports.

-

- ManufacturingAibote possesses a 65,000m2 smart factory, and a 4000m2 building for R&D, and testing. Our factory is equipped with 6 automatic production lines for injection molded parts, 100 digital injection molding machines, 9 RO membrane production lines, and automatic production and testing equipment for filter cartridges, electronic components, waterway boards, etc.

-

- Quality ControlAibote's old laboratory building was built in 2015, it has an area of 2,000 square meters and 35 units of cutting-edge testing equipment from domestic and international suppliers. Currently, we have a new lab building is under construction, which will be 5,000 square meters in floor area.

Our manufacturing plant is made up of 4 main workshops: injection molding workshop, RO membrane rolling workshop, waterway board assembly workshop and whole unit assembly workshop. And it comes equipped with 6 intelligent injection molding lines, 3 dust-free automatic filter membrane production lines, 2 automatic filter cartridge assembling lines and 4 water filter assembling lines. At injection molding workshop, there are 57 robotic manipulators with mold monitoring system that shows the status of molds in real time. In RO rolling workshop, there are anti-UV iso-temperature warehouse to store the filters. In waterway board workshop, you will witness AIBOTE pioneering waterway board production and assembly process. In whole unit assembly workshop, standardized assembly process and inspection procedure is strictly performed.

Please rest assured every Aibote product carries with Aibote people’s most attention and efforts!