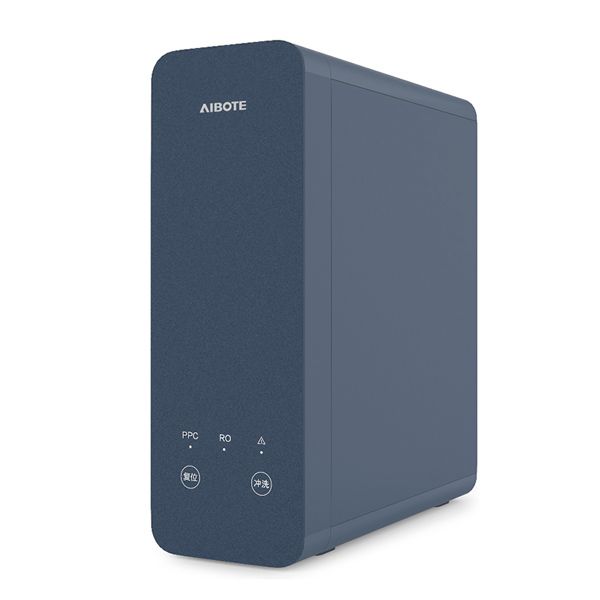

- Filtration System

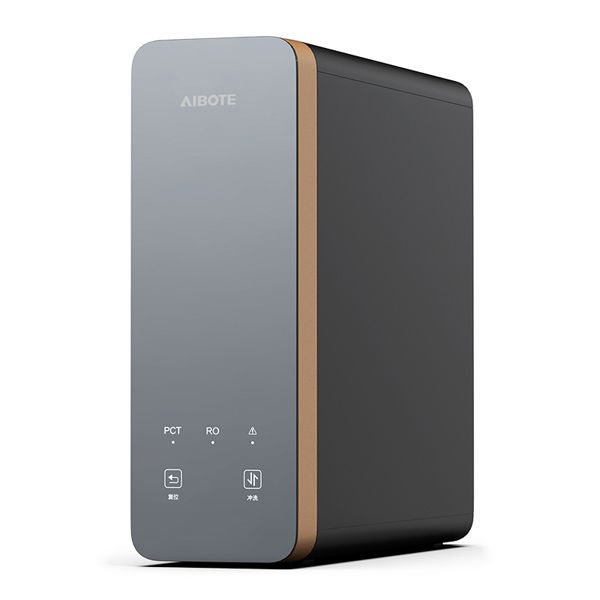

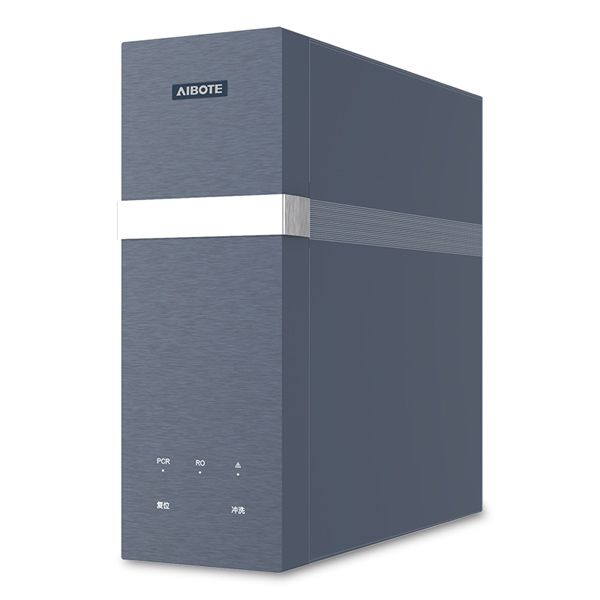

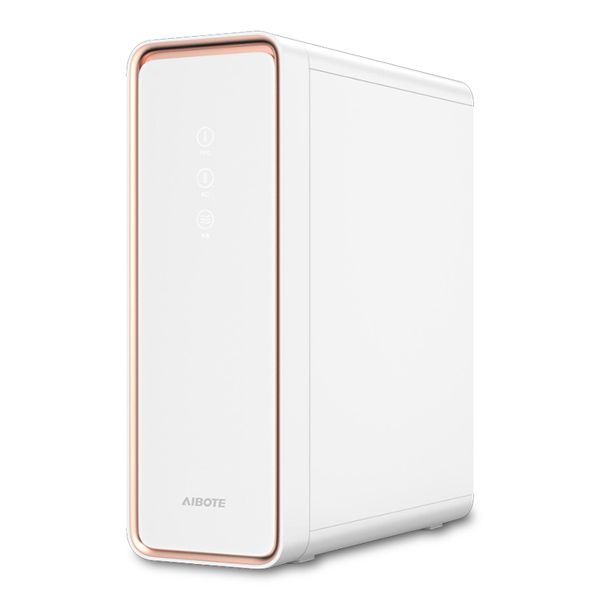

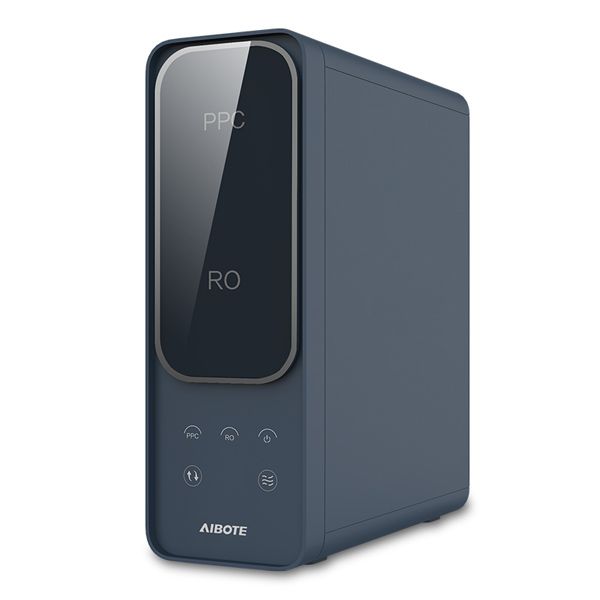

Option 1

First filter: PPC (PP+carbon)

Second filter: ROOption 2

First filter: PCT (PP+carbon+post carbon)

Second filter: ROOption 3

First filter: PCR (PP+carbon+small RO)

Second filter: RO - Purified/Drain Ratio 2:1 pure to drain

Aibote 2-stage RO water filter system produces two kinds of water, filtered water and purified drinking water. The former processed by PPC/PCR/PCT filter cartridge contains no sediments like sand, rust, suspended solids, nematodes and chlorine residuals. Therefore, the filtered water can be used to wash fruits, vegetables and raw meats.

The drinking water purified by two filter cartridges (PPC/PCR/PCT+RO) has removed all tiny substances of 0.0001um-0.001um including heavy metals, bacteria, virus, and antibiotics. This under sink RO system can be configured with a dual outlet faucet which can be switched between filtered water and purified drinking water. The LCD display could conduct real-time monitoring of the drinking water TDS value and the lifetime of filter cartridge.

- High flow with tankless and slim design

- High filtered water yield

- Integrated water manifold module, high-quality assurance

- Intelligent Control: auto flushing, filter life indication, fault alert

- Composite filter development, reducing cost and facilitating filter replacement

- Long service lifespan of RO filter, significantly reducing the cost of use

- Low operating noise (less than 55dBA)

| RO flow available | |||||

| Power | 60W | 80W | 100W | 130W | 150W |

| Voltage | 24V | 24V | 24V | 24V | 36V |

| Purified water flow rate | 1.04L/min | 1.56L/min | 2.08L/min | 2.60L/min | 3.12L/min |

| RO permeate: drain | 2:1 | ||||

| Filtration stages | 4 | ||||

| First filter service life | PCT (PP cotton+carbon+TC post carbon)/9-15months | ||||

| Second filter service life | RO (reverse osmosis)/30-48months | ||||

| Min. input water pressure | 0.1Mpa | ||||

| Max. input water pressure | 0.4Mpa | ||||

| Working pressure | 0.4-0.8MPa | ||||

| Inlet water quality | Municipal water | ||||

| Inlet water temperature | 5-38℃ | ||||

| Water output capacity | Single outlet: 6000L (Two outlets: 6000L+6000L) | ||||

| Ambient temperature | 4-40℃ | ||||

| Installation | Under the sink | ||||

| Gross weight | 11.7kg | 14.6kg | |||

| Product size | 392*135*393mm | 457*135*393mm | |||

| Carton size | 695*192*465mm | 815*192*495mm | |||

| Container (20FT/40GQ/40HQ) | 510pcs/1035pcs/1178pcs | 405pcs/812pcs/940pcs | |||

| The above data is obtained from our laboratory test results. Due to the difference in water quality and water consumption, the replacement cycle of the filter element will be different, depending on the actual use. |

|||||

- Zero stale water technology, PCR water purifier has two RO systems. Besides the normal RO filter cartridge, there is another small RO filter which be put together with PP and carbon in PCR filter cartridge. The water filtered by the small RO system is sent into the big RO system for further purification. No matter how long you have been away on vacation, you just need to turn on the faucet and have higher purity drinking water.

- A design of integrated water manifold modular platform with water leaking sensor ensures no water leakage;

- The 2.08L/min flow rate could fill a cup of 150ml within 4 to 5 seconds;

- Patented double-layer shock absorption design ensures quiet operation by keeping the noise level below 50dB;

- Filter cartridge lifetime is displayed on the body of the water filter system.

- TDS display feature

- Two filtered water dispensing modes (pre-filtration and RO permeate)

- Faucet style

- Various purified water flow (400 GPD-1200 GPD)

- IOT

- Single outlet faucet

- Dual outlet faucet

- LED ring faucet

- Smart faucet